Products

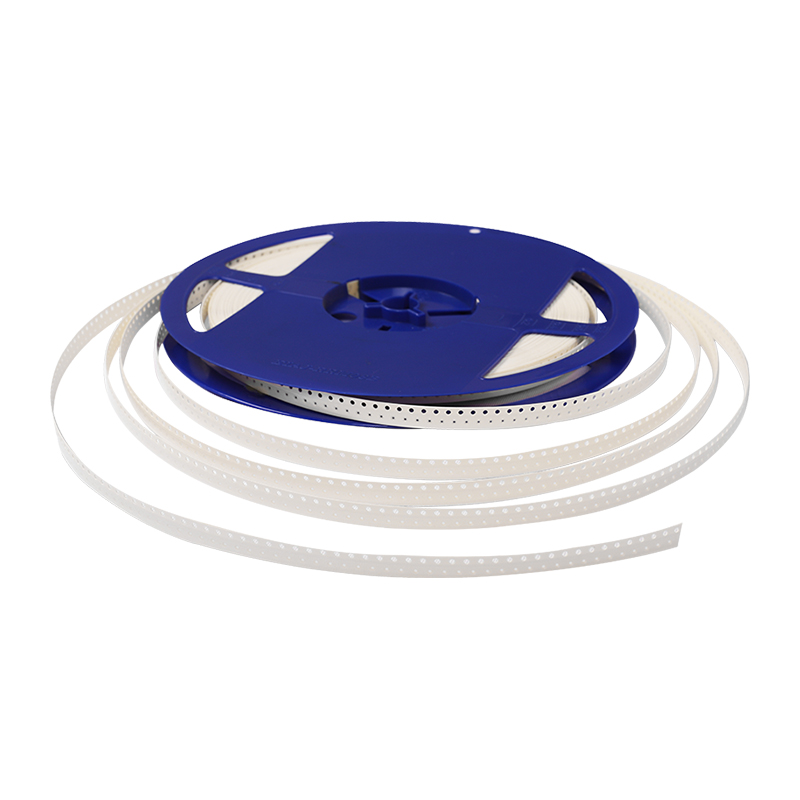

Polycarbonate Carrier Tape

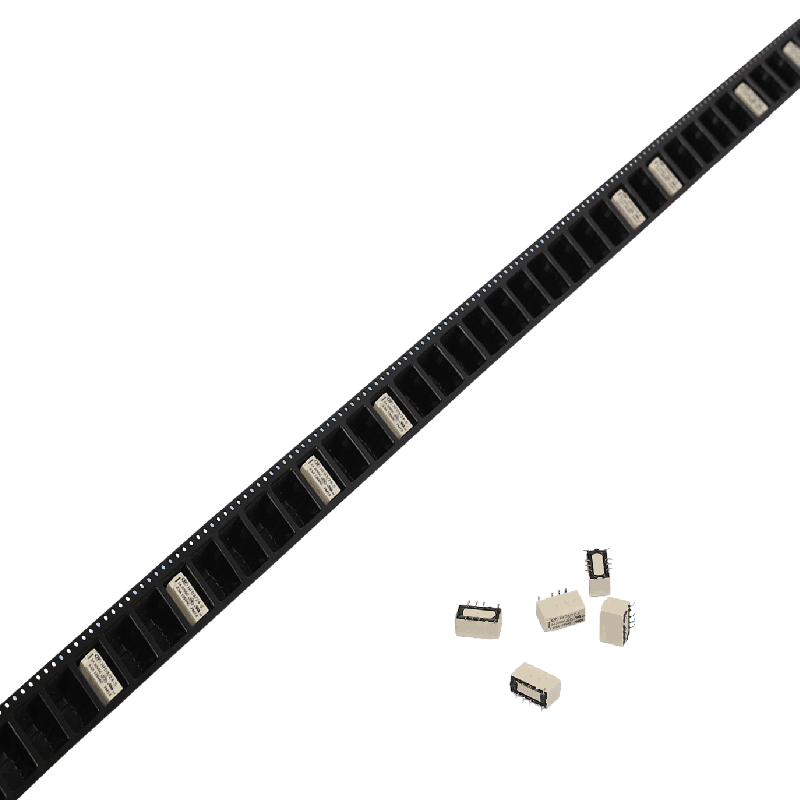

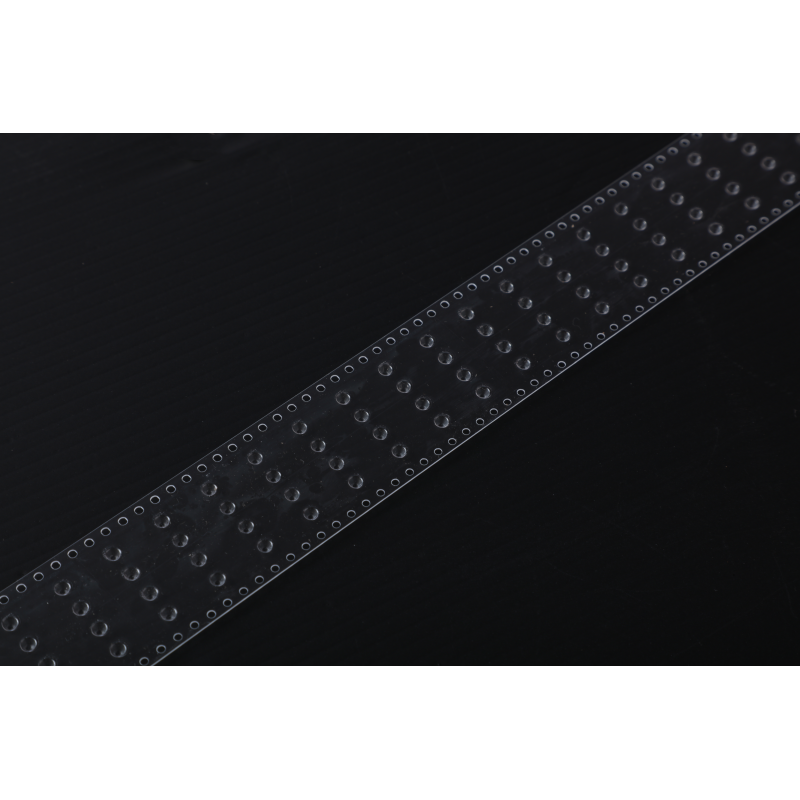

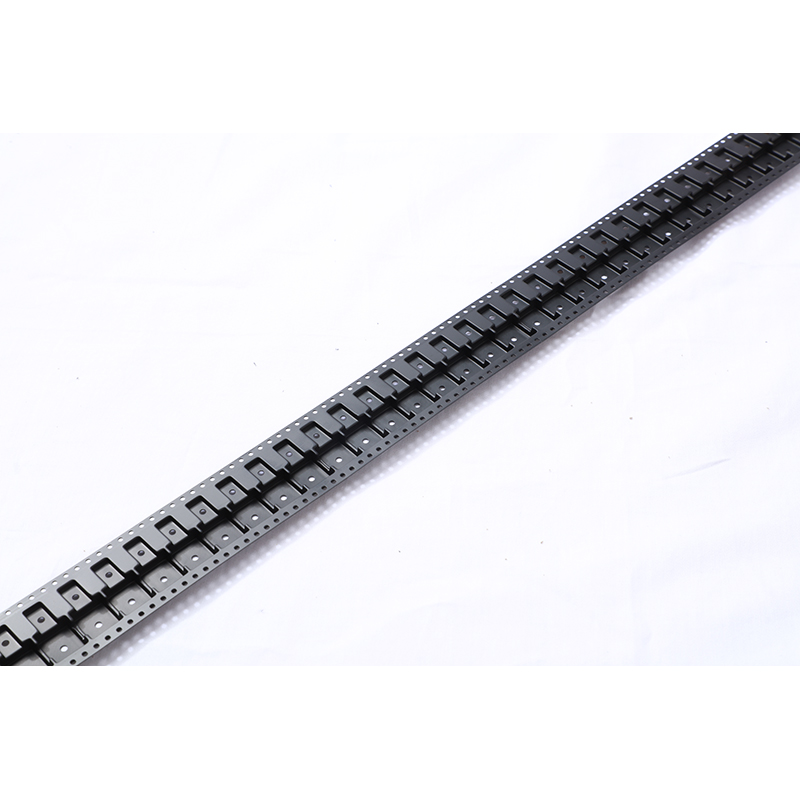

Sinho’s polycarbonate (PC) carrier tape is a continuous, splice free tape with precisely formed pockets to ensure component fit to EIA 481 standard. This materials provide excellent forming performance and strength, high mechanical strength, good dimensional stability and good heat resistance, the clear polycarbonate material also provides high transparency. Sinho’s polycarbonate carrier tape is available in a selection of material types to accommodate a variety of common electrical and electronic parts. There are mainly 3 types, black conductive type, clear non-antistastic type, and clear anti-static type. Polycarbonate black conductive material gives ideal protection to those highly electro-statically sensitive components. Clear polycarbonate normally is non-antistatic material type, it is ideal for passive and mechanical components which are not ESD sensitive. If the ESD safe is needed, clear polycarbonate material could be also anti-static type. Sinho’s polycarbonate carrier tape is optimized for high volume 8mm and 12mm tape widths, engineering for high-precision pockets supporting small components, like LEDs, bare die, ICs, transistor, capacitor...

We utilize both rotary forming processing and linear forming processing to manufacture this polycarbonate material in small 8 and 12mm carrier tape. Mostly this material tape is packaged in level winding format on 22” plastic or recyclable cardboard reels. Single winding format is also available in linear processing upon request. Reel capacity will typically depend upon the pocket depth, pitch and winding format on up to 1000 meters.

Details

|

Optimized for high-precision pockets supporting small components |

Engineered for 8mm to 12mm wide tapes with high volume

Mainly three material types for selection: polycarbonate black conductive type, polycarbonate clear non-antistatic type and polycarbonate clear anti-static type

Used in conjunction with Sinho Antistatic Pressure Sensitive Cover Tapes and Sinho Heat Activated Adhesive Cover Tapes

Both rotary forming machine and linear forming processing could be used on this material

Lengths up to 1000m and small MOQ is available

Single-wind or level-wind format on plastic or recyclable reels for your choice

All SINHO carrier tape is manufactured in accordance with current EIA 481 standard

100% in process pocket inspection

Typical Properties

| Brands |

SINHO |

|

| Color |

Black Conductive / Clear Non-antistatic / Clear Anti-static |

|

| Material |

Polycarbonate (PC) |

|

| Overall Width |

8 mm, 12 mm |

|

| Package |

Single wind Or Level wind format on 22” cardboard reel |

|

| Application |

Small components, like LEDS, bare die, ICs, transistor, capacitor... |

Material Properties

PC Conductive

|

Physical Properties |

Test method |

Unit |

Value |

|

Specific Gravity |

ASTM D-792 |

g/cm3 |

1.25 |

|

Mould Shrinkage |

ASTM D955 |

% |

0.4-0.7 |

|

Mechanical Properties |

Test method |

Unit |

Value |

|

Tensile Strength |

ASTM D638 |

Mpa |

65 |

|

Flexural Strength |

ASTM D790 |

Mpa |

105 |

|

Flexural Modulus |

ASTM D790 |

Mpa |

3000 |

|

Notched Izod Impact Strength (3.2mm) |

ASTM D256 |

J/m |

300 |

|

Thermal Properties |

Test method |

Unit |

Value |

|

Melt Flow Index |

ASTM D1238 |

g/10min |

4-7 |

|

Electrical Properties |

Test method |

Unit |

Value |

|

Surface Resistance |

ASTM D-257 |

Ohm/sq |

104~5 |

|

Flammability Properties |

Test method |

Unit |

Value |

|

Flame Rating @ 3.2mm |

Internal |

NA |

NA |

|

Processing Conditions |

Test method |

Unit |

Value |

|

Barrel Temperature |

|

°C |

280-300 |

|

Mould Temperature |

|

°C |

90-110 |

|

Drying Temperature |

|

°C |

120-130 |

|

Drying Time |

|

Hour |

3-4 |

|

Injection Pressure |

MED-HIGH |

||

|

Hold Pressure |

MED-HIGH |

||

|

Screw Speed |

MODERATE |

||

|

Back Pressure |

LOW |

||

Shelf Life and Storage

Product should be used within 1 year from the date of manufacture.

Store in its original packaging in a climate-controlled environment

where temperature ranges from 0~40℃, relative humidity <65%RHF.

This product is protected from direct sunlight and moisture.

Camber

Meets current EIA-481 standard for camber that is not greater

than 1mm in 250 millimeters length.

Cover Tape Compatibility

| Type |

Pressure Sensitive |

Heat Activated |

|||

| Material |

SHPT27 |

SHPT27D |

SHPTPSA329 |

SHHT32 |

SHHT32D |

| Polycarbonate (PC) |

√ |

√ |

x |

√ |

√ |

Resources

| Physical Properties for Materials | Material Safety Data Sheet |

| Production Process | Safety Tested Reports |