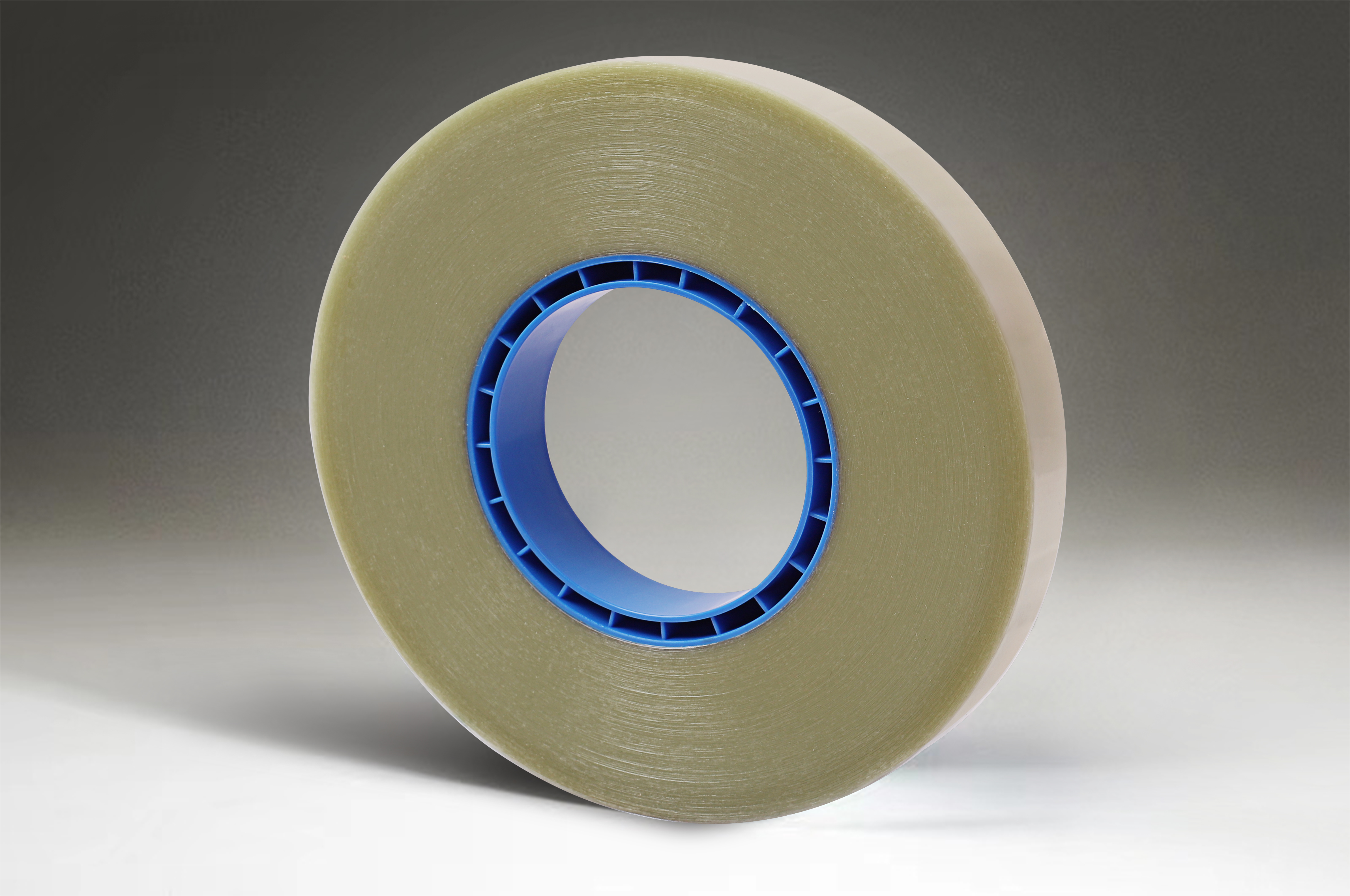

Cover tape is mainly used in the electronic component placement industry. It is used in conjunction with a carrier tape to carry and store electronic components such as resistors, capacitors, transistors, diodes, etc. in the pockets of the carrier tape.

The cover tape is usually based on a polyester or polypropylene film, and is compounded or coated with different functional layers (anti-static layer, adhesive layer, etc.). And it is sealed on top of the pocket in the carrier tape to form a closed space, which is used to protect the electronic components from contamination and damage during transportation.

During the placement of electronic components, the cover tape is peeled off, and the automatic placement equipment accurately positions the components in the pocket through the sprocket hole of the carrier tape, and then takes and places them on the integrated circuit board (PCB board) in sequence.

Classification of cover tapes

A)By the width of the cover tape

To match the different widths of the carrier tape, the cover tapes are made in different widths. Common widths are 5.3 mm (5.4 mm), 9.3 mm, 13.3 mm, 21.3 mm, 25.5 mm, 37.5 mm, etc.

B)By the sealing characteristics

According to the characteristics of bonding and peeling from the carrier tape, cover tapes can be divided into three types: heat-activated cover tape (HAA), pressure-sensitive cover tape (PSA), and new universal cover tape (UCT).

1. Heat-activated cover tape (HAA)

The sealing of the heat-activated cover tape is achieved by the heat and pressure from the sealing block of the sealing machine. While the hot melt adhesive is melted on the sealing surface of the carrier tape, the cover tape is compressed and sealed to the carrier tape. The heat-activated cover tape has no viscosity at room temperature, but becomes sticky after heating.

2.Pressure sensitive adhesive (PSA)

The sealing of the pressure-sensitive cover tape is done by a sealing machine applying continuous pressure through a pressure roller, forcing the pressure-sensitive adhesive on the cover tape to bond to the carrier tape. The two sides adhesive edge of the pressure-sensitive cover tape are sticky at room temperature and can be used without heating.

3. New Universal Cover Tape (UCT)

The peeling force of the cover tapes on the market mainly depends on the adhesive force of the glue. However, when the same glue is used with different surface materials on the carrier tape, the adhesive force varies. The adhesive force of the glue also varies under different temperature environments and aging conditions. In addition, there may be contamination of residual glue during peeling.

To solve these specific problems, a new type of universal cover tape has been introduced to the market. The peeling force does not rely on the adhesive force of the glue. Instead, there are two deep grooves cut on the base film of the cover tape through accurate mechanical processing.

When peeling, the cover tape tears along the grooves, and the peeling force is independent of the adhesive force of the glue, which is only affected by the depth of the grooves and the mechanical strength of the film, in order to ensure the stability of the peeling force. In addition, because only the middle part of the cover tape is peeled off during peeling, while both sides of the cover tape remain adhered to the sealing line of the carrier tape, it also reduces the contamination of residual glue and debris to equipment and components.

Post time: Mar-27-2024