Both SoC (System on Chip) and SiP (System in Package) are important milestones in the development of modern integrated circuits, enabling the miniaturization, efficiency, and integration of electronic systems.

1. Definitions and Basic Concepts of SoC and SiP

SoC (System on Chip) - Integrating the entire system into a single chip

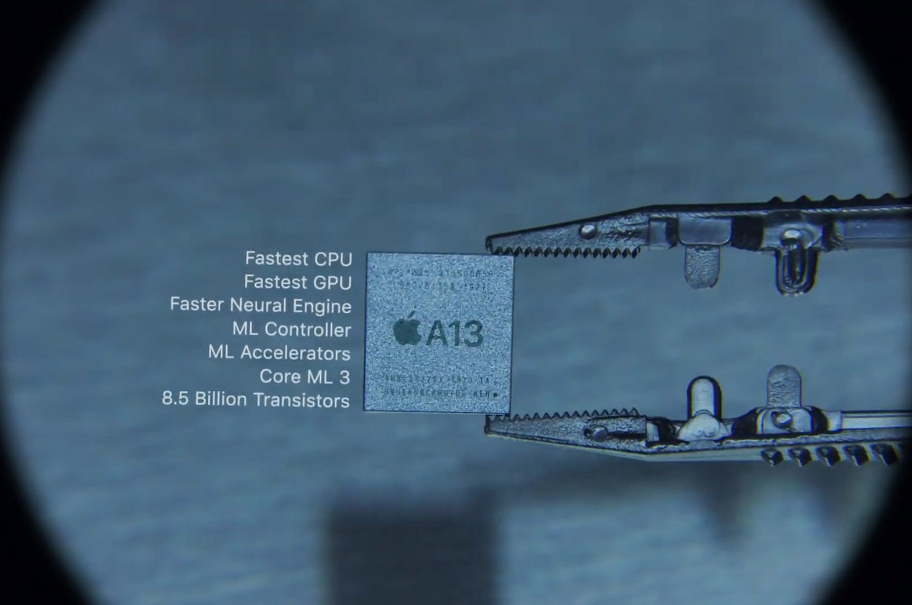

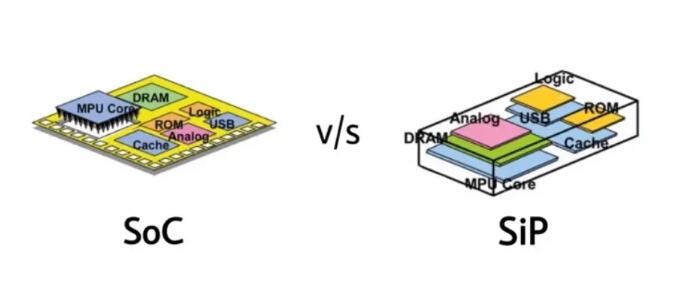

SoC is like a skyscraper, where all functional modules are designed and integrated into the same physical chip. The core idea of SoC is to integrate all the core components of an electronic system, including the processor (CPU), memory, communication modules, analog circuits, sensor interfaces, and various other functional modules, onto a single chip. The advantages of SoC lie in its high level of integration and small size, providing significant benefits in performance, power consumption, and dimensions, making it particularly suitable for high-performance, power-sensitive products. The processors in Apple smartphones are examples of SoC chips.

To illustrate, SoC is like a "super building" in a city, where all functions are designed within, and various functional modules are like different floors: some are office areas (processors), some are entertainment areas (memory), and some are communication networks (communication interfaces), all concentrated in the same building (chip). This allows the entire system to operate on a single silicon chip, achieving higher efficiency and performance.

SiP (System in Package) - Combining different chips together

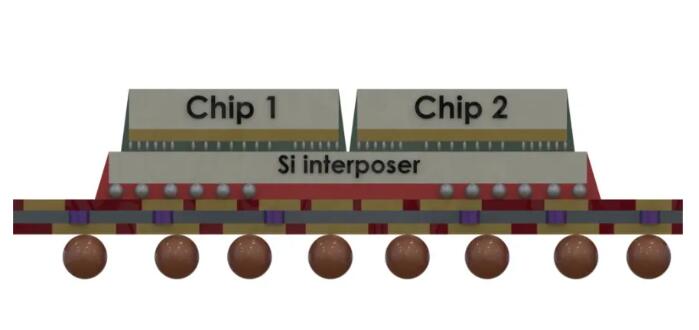

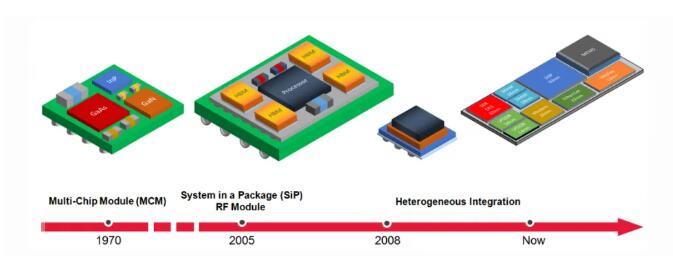

The approach of SiP technology is different. It is more like packaging multiple chips with different functions within the same physical package. It focuses on combining multiple functional chips through packaging technology rather than integrating them into a single chip like SoC. SiP allows multiple chips (processors, memory, RF chips, etc.) to be packaged side by side or stacked within the same module, forming a system-level solution.

The concept of SiP can be likened to assembling a toolbox. The toolbox can contain different tools, such as screwdrivers, hammers, and drills. Although they are independent tools, they are all unified in one box for convenient use. The benefit of this approach is that each tool can be developed and produced separately, and they can be "assembled" into a system package as needed, providing flexibility and speed.

2. Technical Characteristics and Differences between SoC and SiP

Integration Method Differences:

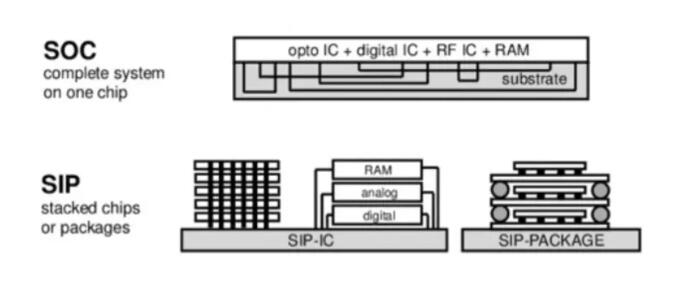

SoC: Different functional modules (such as CPU, memory, I/O, etc.) are directly designed on the same silicon chip. All modules share the same underlying process and design logic, forming an integrated system.

SiP: Different functional chips may be manufactured using different processes and then combined in a single packaging module using 3D packaging technology to form a physical system.

Design Complexity and Flexibility:

SoC: Since all modules are integrated on a single chip, the design complexity is very high, especially for the collaborative design of different modules such as digital, analog, RF, and memory. This requires engineers to have deep cross-domain design capabilities. Moreover, if there is a design issue with any module in the SoC, the entire chip may need to be redesigned, which poses significant risks.

SiP: In contrast, SiP offers greater design flexibility. Different functional modules can be designed and verified separately before being packaged into a system. If an issue arises with a module, only that module needs to be replaced, leaving the other parts unaffected. This also allows for faster development speeds and lower risks compared to SoC.

Process Compatibility and Challenges:

SoC: Integrating different functions such as digital, analog, and RF onto a single chip faces significant challenges in process compatibility. Different functional modules require different manufacturing processes; for example, digital circuits need high-speed, low-power processes, while analog circuits may require more precise voltage control. Achieving compatibility among these different processes on the same chip is extremely difficult.

SiP: Through packaging technology, SiP can integrate chips manufactured using different processes, solving the process compatibility issues faced by SoC technology. SiP allows multiple heterogeneous chips to work together in the same package, but the precision requirements for packaging technology are high.

R&D Cycle and Costs:

SoC: Since SoC requires designing and verifying all modules from scratch, the design cycle is longer. Each module must undergo rigorous design, verification, and testing, and the overall development process may take several years, resulting in high costs. However, once in mass production, the unit cost is lower due to high integration.

SiP: The R&D cycle is shorter for SiP. Because SiP directly uses existing, verified functional chips for packaging, it reduces the time needed for module redesign. This allows for faster product launches and significantly lowers R&D costs.

System Performance and Size:

SoC: Since all modules are on the same chip, communication delays, energy losses, and signal interference are minimized, giving SoC an unparalleled advantage in performance and power consumption. Its size is minimal, making it particularly suitable for applications with high performance and power requirements, such as smartphones and image processing chips.

SiP: Although SiP's integration level is not as high as that of SoC, it can still compactly package different chips together using multi-layer packaging technology, resulting in a smaller size compared to traditional multi-chip solutions. Moreover, since the modules are physically packaged rather than integrated on the same silicon chip, while performance may not match that of SoC, it can still meet the needs of most applications.

3. Application Scenarios for SoC and SiP

Application Scenarios for SoC:

SoC is typically suitable for fields with high requirements for size, power consumption, and performance. For example:

Smartphones: The processors in smartphones (such as Apple's A-series chips or Qualcomm's Snapdragon) are usually highly integrated SoCs that incorporate CPU, GPU, AI processing units, communication modules, etc., requiring both powerful performance and low power consumption.

Image Processing: In digital cameras and drones, image processing units often require strong parallel processing capabilities and low latency, which SoC can effectively achieve.

High-Performance Embedded Systems: SoC is particularly suitable for small devices with stringent energy efficiency requirements, such as IoT devices and wearables.

Application Scenarios for SiP:

SiP has a broader range of application scenarios, suitable for fields that require rapid development and multi-functional integration, such as:

Communication Equipment: For base stations, routers, etc., SiP can integrate multiple RF and digital signal processors, accelerating the product development cycle.

Consumer Electronics: For products like smartwatches and Bluetooth headsets, which have fast upgrade cycles, SiP technology allows for quicker launches of new feature products.

Automotive Electronics: Control modules and radar systems in automotive systems can utilize SiP technology to quickly integrate different functional modules.

4. Future Development Trends of SoC and SiP

Trends in SoC Development:

SoC will continue to evolve towards higher integration and heterogeneous integration, potentially involving more integration of AI processors, 5G communication modules, and other functions, driving further evolution of intelligent devices.

Trends in SiP Development:

SiP will increasingly rely on advanced packaging technologies, such as 2.5D and 3D packaging advancements, to tightly package chips with different processes and functions together to meet the rapidly changing market demands.

5. Conclusion

SoC is more like building a multifunctional super skyscraper, concentrating all functional modules in one design, suitable for applications with extremely high requirements for performance, size, and power consumption. SiP, on the other hand, is like "packaging" different functional chips into a system, focusing more on flexibility and rapid development, particularly suitable for consumer electronics that require quick updates. Both have their strengths: SoC emphasizes optimal system performance and size optimization, while SiP highlights system flexibility and optimization of the development cycle.

Post time: Oct-28-2024