Here is a new solution from the Sinho team that we would like to share with you.

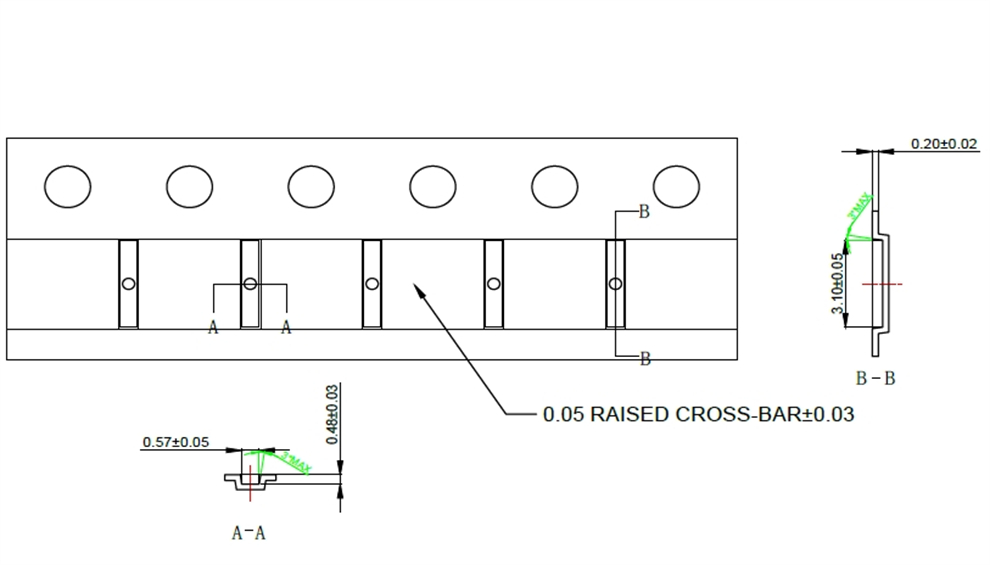

One of Sinho's customers has a die that measures 0.462mm in width, 2.9mm in length, and 0.38mm in thickness with a part tolerances of ±0.005mm. Sinho's engineering team has developed a carrier tape with pocket dimensions of 0.57 × 3.10 × 0.48mm.

Considering that the width (Ao) of the carrier tape is only 0.57mm, a 0.4mm center hole was punched. Furthermore, a 0.03mm raised cross-bar was designed for such a thin pocket to better secure the die in place, preventing it from rolling to the side or flipping completely, and also to prevent the part from sticking to the cover tape during SMT processing.

As always, Sinho's team completed the tool and production within 7 days, the speed that was highly appreciated by the customer, as they urgently needed it for testing at the end of August.

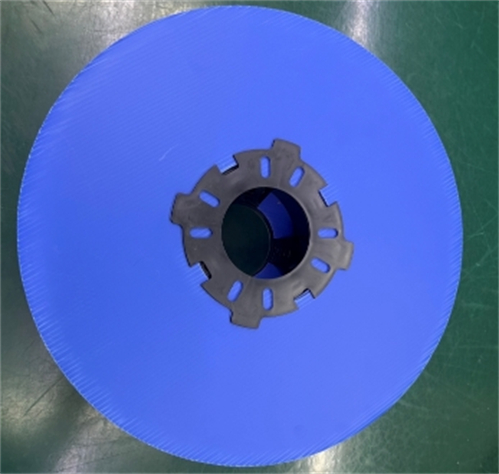

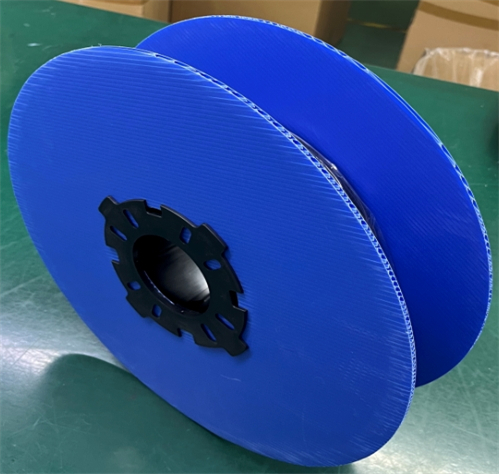

The carrier tape is wound on a PP corrugated plastic reel, making it suitable for clean room requirements and the medical industry, without any papers.

Post time: Sep-02-2024