Cleanliness is next to production standardization requirements for medical device manufacturers (as the old saying goes). Devices built to be inserted within the human body understandably need to meet highest cleanliness standards. A high priority is given to preventing contamination when it comes to medical industry.

Problem:

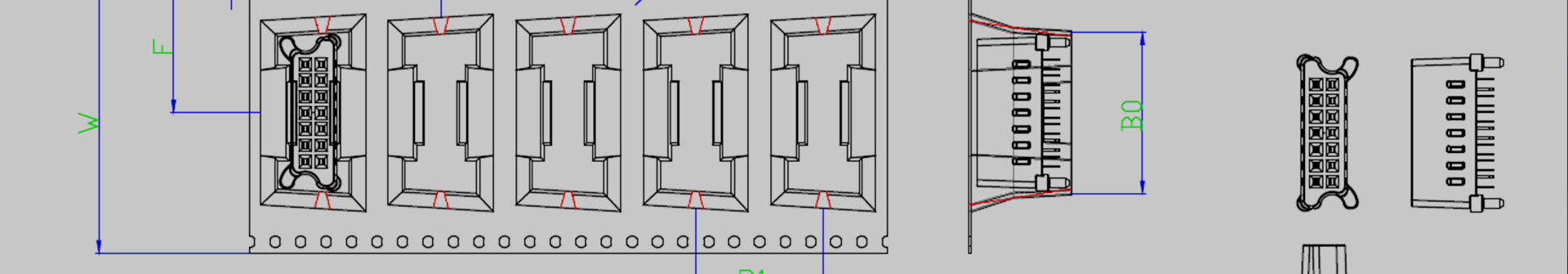

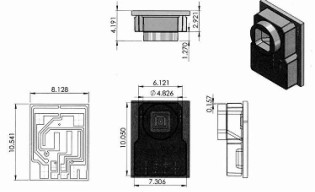

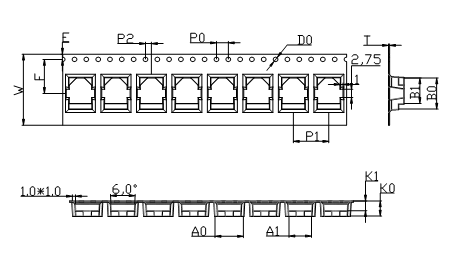

A US manufacturer of high volume medical components need a custom carrier tape. High cleanliness and quality is the basic request as their component need to be packaged in cleanroom when tape and reel in order to protect it from contamination damage. So this custom tape much be formed with “zero” bur. Above all they require 100% accuracy and consistency, keeping tapes cleanly during packaging, storage and shipping.

Solution:

Sinho takes this challenge. Sinho’s R&D team design a custom pocket tape solution with Polyethylene Terephthalate (PET) material. Polyethylene Terephthalate has an outstanding mechanical function, the impact strength is 3-5 times of other sheets, like Polystyrene (PS). The high-density feature greatly reduces the occurrence of burrs in the production process, making “zero” bur become a reality.

In addition, we use 22” PP black plastic board instead of corrugated paper reel, with anti-static coating (the surface resistivity requests less than 10^11 Ω) to avoid paper scraps and reduce dust when packaging. Currently, we are producing over 9.7 million units annually for this project.

Post time: Aug-27-2023